The shape for household candles is 16 mm in diameter, the height of the candle is 240 mm, in the form of 15 pcs

Household candles are still in high demand. Using the proposed budget forms for casting household candles it is very easy to organize the production of household candles at home.

Equipment:

Material: aluminum

Candle diameter - 16 mm;

Candle height - 240 mm

Using:

• Before using the mold for casting candles, it is better to lubricate its surface with vegetable oil, so that the finished cooled candles are easier to separate from the mold.

• Tighten the wick. It is important that the wick is located exactly in the middle of the future candle and is well tensioned.

• Filling the mold with molten wax or paraffin wax. So that in the finished candle it doesn’t turn out ugly seams, you need to fill in one step.

• To prevent cracking of candles, the mold should cool slowly. In the process of cooling, the candle mass decreases in volume. Therefore, it is necessary to use a rush of mold to feed cooling candles with wax.

• Open the mold and remove the candles. Non-thick candles can be removed from the mold when the wax is half frozen and spread out for further cooling on a flat surface.

To organize the continuous production of candles, it is necessary to acquire 2-3 forms. Such a business will not require a large budget from you.

Tentative dates March 20

Is that all right? _________________________________________________________

We answer: Oleg, hello, the possibility of delivery to you is impossible due to the fact that we do not work with people who steal our time and do not advise others.

Candle forms available here:

-

https://clck.ru/EF9SD

On order here:

xsvechi.com

+7 9205819431

https://vk.com/smauzer

https://www.facebook.com/mauzer31

https://ok.ru/sergey.mauzer

https://www.instagram.com/ubersvechi/

. Production time up to 21 days.

The founder of the Transfiguration of the Candlestick Brotherhood, Sergei Mauser, answers you. I am glad to help you with advice and a hint of some principles that can be introduced into the working algorithm. He will work (this principle) not only in production, but also in the sale of finished goods. This principle is called: "The Pareto Principle." It sounds like this:

“20% of the efforts give 80% of the result, and the remaining 80% of the efforts give only 20% of the result”

A simple but ineffably effective principle that I use in practice. Now further! Personally, I profess "labor fanaticism," in conjunction with modern technology. What does it mean? This preference suggests that I devote maximum strength and energy to the first stage of any undertaking. In accordance with the Pareto Principle and my own labor-fanaticism, I invest the maximum allowable charge of money and time in a business project:

It is the turn of marketing and selling the first batch of goods . Do not forget - he is already in the warehouse. Remember what I said about the Pareto Law and 20% of primary efforts? So, at the sales stage, these efforts bring tangible profits. You feel it, and literally - you feel it! It comes to understanding that hot wax in forms is converted into gold coins (income), which must be collected, counted, and ... No, of course, not put in a wallet! Restart to project. Invest the income received in a new production cycle: purchase equipment, restore and increase the supply of industrial raw materials (wax, paraffin, wicks, etc.)

Beginners, in the second stage, they begin to "slip". Not all, of course, but most of them. Marketing moves and agreements with suppliers are critically tested in practice. And here, the Pareto Principle makes itself felt again! Out of the whole mass of “ready to buy” customers, only 20% are actually ready, and the remaining 80% “merge for various reasons. Proven in practice! Therefore, at the first stage, we need a frantic organizational pace, because then, measured work and “marketing slipping” with customers will go. 20% of the remaining customers - there is that minimum that will bring 80% of the profit to your project. Complicated? What do you want? This is a business, with all its “leak-out” consequences. What if I can’t trade, but only produce?

For this, I envisaged the following scheme: a candle manufacturer who does not know how to sell the goods produced can contact us at the Transfiguration Candle Brotherhood! We have our own production and a proven market for finished products. Of course, we do not do “disinterested deeds” - a business requires certain incomes for invested efforts. We boldly take our share of the income (percentage) from jointly sold products (ours and yours).

This is true. The amount of interest may vary, due to various “market circumstances”, but the percentage of sales is always honest and mutually beneficial. Now I’ll tell you about the market for candle products . The market (domestic and foreign), offers demand for the following types of product segment:

Being the founder of the professional guild Brotherhood, and the head of the NGO Sergey Mauser, having exhaustive expert competencies in candle production, I recommend the following actions:

Hello Natalia! Answers the creative director of the NGO NPO Sergey Mauser company, and the leading marketer of the Transfiguration Candle Brotherhood Sergey Mauser!

We sent you the form. We are glad that you have come to us for advice!

. Indeed, the experience of sales of candle equipment showed a characteristic feature: having bought machines or candle molds, quickly learning how to create beautiful products, entrepreneurs cannot sell candles effectively. In the absence of well-established sales, the in-line process breaks down, and business is treading water on the spot. Alas, it often happens.

The candle business is a very specific craft! In addition to pressure and hard work, it requires a considerable share of creativity, multiplied by entrepreneurial ingenuity and business horizons. I’ll explain now! Finished products should go to the masses . A retail buyer gives profit no less, and sometimes more, than a wholesale client.

Novice manufacturers are trying to negotiate with the priors of the temples in their region. They offer to put church candles for ritual service. This is correct, of course, but there is one “BUT"! Many competitors are spinning there. There are large manufacturers and suppliers with established ties with the local Diocese. Most priests and priors simply will not contact you. What for? They are happy with everything.

Therefore, there is a "powerful trick"! And the more powerful it is, the more technological it is . This is Vending Trading! Many people saw vending machines: newspapers, souvenirs, soft drinks, cigarettes. However, retail sales mechanisms that sell not only these categories of goods. Church and decorative candles are also sold through vending equipment. Moreover, the vending machines themselves are very inexpensive!

Having installed several vending machines in various points of the city, the entrepreneur will be able to count on the uninterrupted sale of finished candle products . The main thing to consider is “consumer routes” and optimally low prices for products! Such equipment should be installed in crowded places, around Orthodox churches, monasteries, and even - salons of funeral services. People who go to temple services or simply, in passing, “light candles” to patron saints will gladly buy a church candle at a price lower than they are sold in churches. And the local abbot will quickly understand the benefits of being close to the church with inexpensive church candles. He is also your customer!

There is a nuance - try to avoid the name of the product “church candles” . Who knows, what feelings do you hurt? Suddenly, cause the indignant attacks of the Orthodox clergy? This we do not need. So you need to name the products so that there is no opportunity to complain about vigilant competitors! We will name, for example: “God's Candles,” “Heavenly Candle,” “Ritual Candles,” “Icon Candles,” and so on. like that. The form itself, materials, and other “church conditions” can be 1: 1 for candles traded at temple shops. This is not a problem, since the Church does not have a “similarity” patent. People will appreciate your efforts with the ruble!

This method is successfully used in the implementation of the candle products of the Transfiguration Candlestick Brotherhood . The method is proven. Sergey Mauser - does not give empty advice, for a red word! Only on business - strictly in the commercial interests of partners and regular customers! If we give recommendations on the implementation of candle products, I will add such a consideration. Vending trade requires continuous production of candles. The warehouse should be replenished constantly. It is important!

Delivery and charging of candles into automatic machines should be regular and systemic. To do this, expand production capacity. The "Transfiguration Candle Brotherhood" has the opportunity to supply professional equipment for candle production. This is a drum type candle machine for continuous continuous production of church candles of various diameters. The prices are optimal, and taking into account discounts, preferences and "technical support" - a profitable purchase! Here is the video on the machine:

The cost of the “Candle Drum” will pay off in the coming weeks of the trading process, through vending machines. You can’t be stingy here - it’s about serious business and excellent return on investment! Moreover, "vending machines" can not be bought, but leased. This is a significant cost saving for marketing development. Marketing is a creative thing! It is like a game, with many unknowns, where the winner gets a significant profit and joy from the results achieved. Excitement and Creativity - these are the most valuable qualities of a successful businessman! Candle production, meets these requirements, like no other.

While writing the answer and thinking about the candle craft as a successful business, I thought that Excitement and Creativity did not pass me by. Having a problem - I see a personal challenge in it; I start to decide - I show Creativity and indispensable Excitement! Only full involvement in the production process can help a businessman achieve good results.

Excitement and Creativity are indispensable companions for success. Develop them. Achieve high incomes and be successful!

We answer, Oksana, hello. Yes, you can purchase an aluminum mold for candles. To begin with, we offer 15+ photos of aluminum forms for candles, which you should look at instead of taking antidepressants

We answer: Olga good afternoon. Below are 20 photos of paraffin that will conquer you with their zest:

The following aspects are related to the rules for using wax:

For example, adding fir or ginger oil to melted paraffin will allow you to get rid of pain during an exacerbation of a joint disease, and also partially relieve inflammation after the first application.

Paraffin compresses are used every day. But you should be careful in applying heat therapy, since excessive heating of the joint can turn into troubles for the user.

That's all. He hugged everyone. Sergey Mauser. Come for paraffin here

Which company or store will seem more successful to you: Where in a modest box are modest bottles of wine with ordinary corks or where is a chic stand with chic bottles of wine, sealed with wax?

What is the best way to see clients, each of whom rushes inadvertently to a colorful stand to take a chic bottle of wine, sealed with wax, or or send them to a modest wine box with ordinary corks?

We have been doing bottle waxing since 2020 and we know everything about it.

High adhesion to glass, durable, does not crumble, withstands cold and heat.

A large palette of colors and dozens of ready-made ideas for using wax for decorative purposes.

It can be implemented both in mass and single production using automatic or semi-automatic lines, as well as the manual method.

Increases product recognition. Stands out on a shelf. Protects products from fakes.

The use of polylaminate and heat shrink capsules is not required.

The material is insensitive to moisture and has high strength. In addition, the particles of minerals contained in the wax are larger than, for example, in a mixture for sealing letters. This makes it thick, so the wax on the bottle does not flow well and solidifies quickly.

Wine bottle waxes have been used for centuries to seal bottles. It is very simple to use, it is necessary to melt the wax, then dip the neck of the bottle into it to the desired level.

The unique formula of bottle wax , thanks to which the wax does not crack, does not crumble, does not crumble from the surface.

Clogging process

At the initial stage, grind the wax into small pieces. Then you need to put the raw materials in a can of canned food and heat the water in a pan, filled by one third. Next, you need to lower the tin can with wax into a hot liquid (observing safety precautions), and put the pan on a slow fire. Soon after, the wax will begin to melt. To achieve a uniform consistency, stir the composition periodically.

At the same time, bottle caps must be aligned (masking tape can be used). At the next stage, the bottles are cooled, and then the plugging process takes place directly (it is important to ensure that they surround the bottle necks as tightly and evenly as possible). It remains to plug our containers with liquid wax. To do this, lower the neck of the bottle into the pan with the resulting composition for 2 minutes, after which they should be removed, wait 20-25 minutes until the wax has hardened, and the glass containers can be transferred to the place of their direct storage.

Producers planning long-term storage of wine can also seal the bottle with WAX. For example, for scientific purposes or for the commercialization of the process for the sale of long-term aged drinks at prices many times higher than the cost of wines two to three years ago.

WAX sealed the Massandra wine collection, listed in the Guinness Book of Records. It has been formed since the end of the 19th century and includes many unique wines, including the sherry of 1775. On average, replacing the cork and refilling the Wax mixture is done every 20 years.

Today, VOSK is actively used by the creators of copyrighted wine collections in private wineries. This is partly due to the lack of production facilities and automated lines for durable bottle corking and tightness. In addition, this design increases the credibility of the author’s collection in the eyes of potential consumers.

THAT'S ALL I WANTED TO SAY. ALL HUGS. COME BEYOND THE WAX HERE

Подробнее: https://xsvechi.com/p57995403-forma-dlya-hozyajstvennyh.html

Equipment:

| • single-row form, equipped with a device for centering the candle wick and opening tide | - 1 PC |

| • screw clamps | - 6 pcs. |

| • number of candles in the form | - 15 pcs. |

Candle diameter - 16 mm;

Candle height - 240 mm

Using:

• Before using the mold for casting candles, it is better to lubricate its surface with vegetable oil, so that the finished cooled candles are easier to separate from the mold.

• Tighten the wick. It is important that the wick is located exactly in the middle of the future candle and is well tensioned.

• Filling the mold with molten wax or paraffin wax. So that in the finished candle it doesn’t turn out ugly seams, you need to fill in one step.

• To prevent cracking of candles, the mold should cool slowly. In the process of cooling, the candle mass decreases in volume. Therefore, it is necessary to use a rush of mold to feed cooling candles with wax.

• Open the mold and remove the candles. Non-thick candles can be removed from the mold when the wax is half frozen and spread out for further cooling on a flat surface.

To organize the continuous production of candles, it is necessary to acquire 2-3 forms. Such a business will not require a large budget from you.

Perhaps, because for the cone there are no all parameters in the calculation form

April 8, 2020A letter from our pseudo-client: “ It is possible, since for a cone there are not all parameters in the calculation form.

So total: 55,840 + 4,500 = 60,340 rublesTentative dates March 20

Is that all right? _________________________________________________________

This message was sent from the site http: //sergeymauser.rf

Sincerely, Leg Colegcoit@mail.ru ”We answer: Oleg, hello, the possibility of delivery to you is impossible due to the fact that we do not work with people who steal our time and do not advise others.

Candle forms available here:

-

https://clck.ru/EF9SD

On order here:

xsvechi.com

+7 9205819431

https://vk.com/smauzer

https://www.facebook.com/mauzer31

https://ok.ru/sergey.mauzer

https://www.instagram.com/ubersvechi/

. Production time up to 21 days.

Candlestick production and income: How to make money?

Candle forms available here: https://clck.ru/EF9SDThe founder of the Transfiguration of the Candlestick Brotherhood, Sergei Mauser, answers you. I am glad to help you with advice and a hint of some principles that can be introduced into the working algorithm. He will work (this principle) not only in production, but also in the sale of finished goods. This principle is called: "The Pareto Principle." It sounds like this:

“20% of the efforts give 80% of the result, and the remaining 80% of the efforts give only 20% of the result”

A simple but ineffably effective principle that I use in practice. Now further! Personally, I profess "labor fanaticism," in conjunction with modern technology. What does it mean? This preference suggests that I devote maximum strength and energy to the first stage of any undertaking. In accordance with the Pareto Principle and my own labor-fanaticism, I invest the maximum allowable charge of money and time in a business project:

- I make the necessary equipment (matrices, machine tools, tanks, boilers);

- I get industrial raw materials (wax, paraffin, wicks, oil, etc.);

- I make additional (reserve) financing of the project;

- I study the market and the level of demand for the manufactured goods (Internet);

- start industrial production;

- I sell products to the final consumer.

It is the turn of marketing and selling the first batch of goods . Do not forget - he is already in the warehouse. Remember what I said about the Pareto Law and 20% of primary efforts? So, at the sales stage, these efforts bring tangible profits. You feel it, and literally - you feel it! It comes to understanding that hot wax in forms is converted into gold coins (income), which must be collected, counted, and ... No, of course, not put in a wallet! Restart to project. Invest the income received in a new production cycle: purchase equipment, restore and increase the supply of industrial raw materials (wax, paraffin, wicks, etc.)

Beginners, in the second stage, they begin to "slip". Not all, of course, but most of them. Marketing moves and agreements with suppliers are critically tested in practice. And here, the Pareto Principle makes itself felt again! Out of the whole mass of “ready to buy” customers, only 20% are actually ready, and the remaining 80% “merge for various reasons. Proven in practice! Therefore, at the first stage, we need a frantic organizational pace, because then, measured work and “marketing slipping” with customers will go. 20% of the remaining customers - there is that minimum that will bring 80% of the profit to your project. Complicated? What do you want? This is a business, with all its “leak-out” consequences. What if I can’t trade, but only produce?

For this, I envisaged the following scheme: a candle manufacturer who does not know how to sell the goods produced can contact us at the Transfiguration Candle Brotherhood! We have our own production and a proven market for finished products. Of course, we do not do “disinterested deeds” - a business requires certain incomes for invested efforts. We boldly take our share of the income (percentage) from jointly sold products (ours and yours).

This is true. The amount of interest may vary, due to various “market circumstances”, but the percentage of sales is always honest and mutually beneficial. Now I’ll tell you about the market for candle products . The market (domestic and foreign), offers demand for the following types of product segment:

Church candles;- Candles are aromatic and decorative;

- Esoteric candles;

- Medical candles.

Being the founder of the professional guild Brotherhood, and the head of the NGO Sergey Mauser, having exhaustive expert competencies in candle production, I recommend the following actions:

- Buy enough minimum equipment to increase the number of machines and additional equipment in the production hall of your enterprise from the very first profits from the sale of products. The required minimum is equipment from 80 thousand rubles to 120 thousand rubles. (Verified in practice)

- Take the equipment from the same supplier (“Sergey Mauser NGO”).

- When buying, require the conclusion of contracts for the supply of: spare parts, raw materials and technical assistance, at internal corporate prices (enter into a partnership with PSB).

- Discuss the possibility of joint product sales with Sergey Mauser.

- Do not expect easy money, from minimal investment! Buy the maximum possible equipment and technology to count on guaranteed success of the enterprise.

- Discuss doubts and plans with partners from PSB - they will prompt and teach!

- Remember - income from first sales, let the increase in the number of equipment!

Company Website: https://xsvechi.com/- Phones: +79205819431 / +79205965852

- VKontakte: https://vk.com/mauzers31

- Instagram: https://www.instagram.com/ubersvechi/

- Y-Tube: https://www.youtube.com/channel/UCqxJLO5AgSoCsupVvQtpY2w?view_as=subscriber

I really want to get a shape for cone shaped candles

April 8, 2020“Vending move” in the sale of candles: Secrets of Sergey Mauser

We have received a letter: “ I am very sorry for the missed opportunity. I really want to get a shape for cone-shaped candles, so I’m ready to stay on a 10-place form No. 40, order number 093 at the price of 9507, 96 rubles. I hope to receive a gift by March 8th. Thank. Sincerely, N. Ponomareva. . "Hello Natalia! Answers the creative director of the NGO NPO Sergey Mauser company, and the leading marketer of the Transfiguration Candle Brotherhood Sergey Mauser!

We sent you the form. We are glad that you have come to us for advice!

. Indeed, the experience of sales of candle equipment showed a characteristic feature: having bought machines or candle molds, quickly learning how to create beautiful products, entrepreneurs cannot sell candles effectively. In the absence of well-established sales, the in-line process breaks down, and business is treading water on the spot. Alas, it often happens.

The candle business is a very specific craft! In addition to pressure and hard work, it requires a considerable share of creativity, multiplied by entrepreneurial ingenuity and business horizons. I’ll explain now! Finished products should go to the masses . A retail buyer gives profit no less, and sometimes more, than a wholesale client.

Novice manufacturers are trying to negotiate with the priors of the temples in their region. They offer to put church candles for ritual service. This is correct, of course, but there is one “BUT"! Many competitors are spinning there. There are large manufacturers and suppliers with established ties with the local Diocese. Most priests and priors simply will not contact you. What for? They are happy with everything.

Therefore, there is a "powerful trick"! And the more powerful it is, the more technological it is . This is Vending Trading! Many people saw vending machines: newspapers, souvenirs, soft drinks, cigarettes. However, retail sales mechanisms that sell not only these categories of goods. Church and decorative candles are also sold through vending equipment. Moreover, the vending machines themselves are very inexpensive!

Having installed several vending machines in various points of the city, the entrepreneur will be able to count on the uninterrupted sale of finished candle products . The main thing to consider is “consumer routes” and optimally low prices for products! Such equipment should be installed in crowded places, around Orthodox churches, monasteries, and even - salons of funeral services. People who go to temple services or simply, in passing, “light candles” to patron saints will gladly buy a church candle at a price lower than they are sold in churches. And the local abbot will quickly understand the benefits of being close to the church with inexpensive church candles. He is also your customer!

There is a nuance - try to avoid the name of the product “church candles” . Who knows, what feelings do you hurt? Suddenly, cause the indignant attacks of the Orthodox clergy? This we do not need. So you need to name the products so that there is no opportunity to complain about vigilant competitors! We will name, for example: “God's Candles,” “Heavenly Candle,” “Ritual Candles,” “Icon Candles,” and so on. like that. The form itself, materials, and other “church conditions” can be 1: 1 for candles traded at temple shops. This is not a problem, since the Church does not have a “similarity” patent. People will appreciate your efforts with the ruble!

This method is successfully used in the implementation of the candle products of the Transfiguration Candlestick Brotherhood . The method is proven. Sergey Mauser - does not give empty advice, for a red word! Only on business - strictly in the commercial interests of partners and regular customers! If we give recommendations on the implementation of candle products, I will add such a consideration. Vending trade requires continuous production of candles. The warehouse should be replenished constantly. It is important!

Delivery and charging of candles into automatic machines should be regular and systemic. To do this, expand production capacity. The "Transfiguration Candle Brotherhood" has the opportunity to supply professional equipment for candle production. This is a drum type candle machine for continuous continuous production of church candles of various diameters. The prices are optimal, and taking into account discounts, preferences and "technical support" - a profitable purchase! Here is the video on the machine:

The cost of the “Candle Drum” will pay off in the coming weeks of the trading process, through vending machines. You can’t be stingy here - it’s about serious business and excellent return on investment! Moreover, "vending machines" can not be bought, but leased. This is a significant cost saving for marketing development. Marketing is a creative thing! It is like a game, with many unknowns, where the winner gets a significant profit and joy from the results achieved. Excitement and Creativity - these are the most valuable qualities of a successful businessman! Candle production, meets these requirements, like no other.

While writing the answer and thinking about the candle craft as a successful business, I thought that Excitement and Creativity did not pass me by. Having a problem - I see a personal challenge in it; I start to decide - I show Creativity and indispensable Excitement! Only full involvement in the production process can help a businessman achieve good results.

Excitement and Creativity are indispensable companions for success. Develop them. Achieve high incomes and be successful!

Our contacts:

Company Website: http: //xn—-8sbhhbcnn2a9aib8a.xn--p1ai/- Actual address: Russian Federation, Kursk, Kulakova Avenue 12.

- Phone: +7 (920) 596-58-52

- E-mail: angel4495@yandex.ru

- YouTube Channel: https://www.youtube.com/channel/UCqxJLO5AgSoCsupVvQtpY2w

15+ photos of aluminum candle molds to look at instead of taking antidepressants

April 7, 2020We have received a letter: “Hello. Can I buy an aluminum mold for candles? I’m from the courses of Svetlana Tsyganova ”

We answer, Oksana, hello. Yes, you can purchase an aluminum mold for candles. To begin with, we offer 15+ photos of aluminum forms for candles, which you should look at instead of taking antidepressants

- The shape for household candles is 16 mm in diameter, the height of the candle is 200 mm, in the form of 20 pcs. Read more: https://xsvechi.com/p57995392-forma-dlya-hozyajstvennyh.html

- Household candles are still in high demand. Using the proposed budgetary wooden molds for casting household candles, it is very easy to organize the production of household candles at home.

- Equipment:

| • single-row form, equipped with a device for centering the candle wick and opening tide | - 1 PC |

| • screw clamps | - 6 pcs. |

| • number of candles in the form | - 20 pcs. |

- Material: aluminum

- Candle diameter - 16 mm

- Candle height - 200 mm

- Using:

- • Before using the mold for casting candles, it is better to lubricate its surface with vegetable oil, so that the finished cooled candles are easier to separate from the mold.

- • Tighten the wick. It is important that the wick is located exactly in the middle of the future candle and is well tensioned.

- • Filling the mold with molten wax or paraffin wax. So that in the finished candle it doesn’t turn out ugly seams, you need to fill in one step.

- • To prevent cracking of candles, the mold should cool slowly. In the process of cooling, the candle mass decreases in volume. Therefore, it is necessary to use a rush of mold to feed cooling candles with wax.

- • Open the mold and remove the candles. Non-thick candles can be removed from the mold when the wax is half frozen and spread out for further cooling on a flat surface.

- To organize the continuous production of candles, it is necessary to acquire 2-3 forms. Such a business will not require a large budget from you.

- Read more: https://xsvechi.com/p57995392-forma-dlya-hozyajstvennyh.html

- Aluminum mold for 9 places for the manufacture of conventional church candles No. 5. Price: 13 863p

- The candle mold is designed for the manual production of church candles from wax.

- The article for the order is "001".

- Completeness:

- - single row;

- - aluminum mold;

- - with the device for centering the candle wick and the breaking tide;

- - screw clamps;

- Characteristics:

- - the shape of the upper end of the candle is spherical;

- - candle number - No. 5;

- - diameter - 16 mm;

- - candle length - 450 mm.

- - the number of slots for simultaneous filling - 9.

- Fairytale molds for candles number 2.

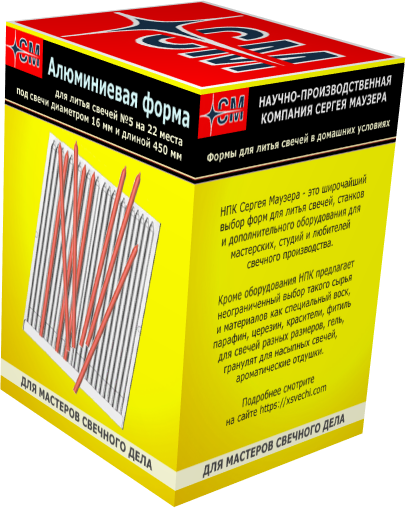

- Aluminum mold for 22 places for the manufacture of conventional church candles No. 5 (Class 1) Price: 27 174p

- The candle mold is designed for the manual production of church candles from wax.

- Read more: https://xsvechi.com/p57995392-forma-dlya-hozyajstvennyh.html

- Fairytale molds for candles number 3.

- Aluminum mold for 9 places for the manufacture of conventional church candles No. 5 (Class 2) / Price: 13 863p

- The candle mold is designed for the manual production of church candles from wax.

- The article for the order is "003".

- Completeness:

- - single row;

- - aluminum mold;

- - with the device for centering the candle wick and the breaking tide;

- - screw clamps;

- Characteristics:

- - the shape of the upper end of the candle is spherical;

- - candle number - No. 5;

- - diameter - 16 mm;

- - candle length - 450 mm.

- - the number of slots for simultaneous filling - 9.

- Fairytale molds for candles No. 4

- Aluminum mold for 22 places for the manufacture of conventional church candles No. 5 (Class 2). Price: 29 781p

- The candle mold is designed for the manual production of church candles from wax.

- Read more: https://xsvechi.com/p57995392-forma-dlya-hozyajstvennyh.html

- The article for the order is "004".

- Completeness:

- - single row;

- - aluminum mold;

- - with the device for centering the candle wick and the breaking tide;

- - screw clamps;

- Characteristics:

- - the shape of the upper end of the candle is spherical;

- - candle number - No. 5;

- - diameter - 16 mm;

- - candle length - 450 mm.

- - the number of slots for simultaneous filling - 22.

- Fairytale molds for candles No. 5

- Aluminum mold for 9 places for the manufacture of conventional church candles No. 5 (Class 3). Price: 14 237p

- The candle mold is designed for the manual production of church candles from wax.

- Read more: https://xsvechi.com/p57995392-forma-dlya-hozyajstvennyh.html

- Read more: https://xsvechi.com/p57995392-forma-dlya-hozyajstvennyh.html

- Fairytale molds for candles No. 6

- Aluminum mold for 22 places for the manufacture of conventional church candles No. 5 (Class 3). Price: 30 683p

- The candle mold is designed for the manual production of church candles from wax.

- Read more: https://xsvechi.com/p57995392-forma-dlya-hozyajstvennyh.html

- Fairytale molds for candles No. 7

- Aluminum mold for 9 places for the manufacture of conventional church candles No. 5 (Class 4) Price: 12 792p

- The candle mold is designed for the manual production of church candles from wax.

- Read more: https://xsvechi.com/p57995392-forma-dlya-hozyajstvennyh.html

- The article for the order is "007".

- Completeness:

- - single row;

- - aluminum mold;

- - with the device for centering the candle wick and the breaking tide;

- - screw clamps;

- Characteristics:

- - the shape of the upper end of the candle is spherical;

- - candle number - No. 5;

- - diameter - 16 mm;

- - candle length - 450 mm.

- - the number of slots for simultaneous filling - 9.

- Bonus

- The buyer of the form is given a gift from NPK Sergey Mauser.

- The gift includes:

- 1. A kilogram of wax.

- 2. The bay of a special wick.

- For all questions regarding working with the form, formulations, raw materials, prices - please contact !

- We will answer all questions within a day.

- Read more: https://xsvechi.com/p57995392-forma-dlya-hozyajstvennyh.html

- Read more: https://xsvechi.com/p57995392-forma-dlya-hozyajstvennyh.html

20 photos of paraffin that will conquer you with its zest

April 7, 202020 photos of paraffin that will conquer you with its zest

Letter from our client: “ Good morning! Throw off a photo that corresponds to paraffin in a 1kg briquette. ”We answer: Olga good afternoon. Below are 20 photos of paraffin that will conquer you with their zest:

- Paraffin BLACK EXTRA

- According to most users, one of the best methods for treating various joint diseases is based on the use of heat therapy using paraffin.

- Its useful properties have been known to medicine for a long time. Specialists highlight the described tool as the most effective in the treatment of diseases of the musculoskeletal system, viral manifestations, as well as bruises, sprains and many other ailments.

- The healing properties of paraffin

- The therapeutic effect of paraffin for human joints is explained by its high heat capacity, but with a low thermal conductivity.

- So, paraffin begins its melting already at 52 degrees Celsius. Due to the low thermal conductivity, paraffin applied to the skin leads to an increase in the temperature of the treated area by only two degrees Celsius.

- As a result, it is impossible to get a burn when using heat therapy based on paraffin as a treatment, but a positive result due to long-term heat storage is achieved quickly.

- The tool leads to rapid softening of the upper layer of the epidermis , which significantly increases the result from the procedure.

- The increase in intercellular space and the expansion of pores contribute to the rapid penetration of heat. If paraffin is applied to the inflamed area, this property helps to eliminate excess moisture due to increased sweating.

- Due to the expansion of pores, accumulated toxins and harmful substances are eliminated from the body .

- Paraffin, heating the skin, leads to an increase in blood circulation , which significantly reduces inflammation.

- Paraffin masks moisturize the skin and make it more elastic.

- Paraffin red brown

- Brown Monocolor Paraffin

Proper Use of Paraffin

Paraffin should be used correctly to avoid burns or any other damage.The following aspects are related to the rules for using wax:

- Heated paraffin in a water bath . There is little disagreement about the heating temperature. Some argue that it is necessary to reach a temperature at which the substance will completely melt and turn into a viscous mass.

- The cooled paraffin (up to about 60 degrees Celsius) is applied to the affected area. In other sources, you can find a prerequisite in the form of heating paraffin to only 51 degrees. It all depends on the method of application. Follow the instructions for your treatment.

- Brown paraffin

- Paraffin pink

- White paraffin

- Paraffin treatment for joints may not be the only one .

- You can not use paraffin in the diagnosis of hypertension, varicose veins or diabetes . Also, you can not apply the product to the skin in the presence of ulcers, wounds, acne and other rashes.

Indications for use

Paraffin is used to treat joint diseases such as:- all types of inflammatory diseases, but without the presence of a purulent process, for example, arthritis;

- degenerative joint diseases - osteochondrosis, arthrosis and other diseases;

- joint treatment with beeswax is recommended after an injury, sprain;

- Yellow paraffin

- articular tunnel syndromes - cubital canal or snapping finger syndrome.

Contraindications

In no case should you resort to the use of paraffin for diseases:- associated with ongoing inflammatory purulent processes in the joint;

- in the presence of tumors of bones and adjacent tissues - lipoma, fibroma, neuroma and others;

- with a certain tendency to hemorrhage in the joint cavity;

- internal organs - cirrhosis of the liver, genitourinary system in women and other negative manifestations.

Wax Based Recipes

There are several methods for treating joint diseases using paraffin:- To treat joints in the arms or legs, melt the paraffin to a liquid state. Dip your hands or feet into it, remove from the composition and wait for the formation of a protective layer - hardening of paraffin . Place the treated limbs in a plastic bag. Wrap them in a woolen blanket or wrap them in a scarf. A treatment session will take 15-20 minutes. As necessary and depending on the disease, the course may include from 3 to 30 procedures.

- Peach Paraffin

- Paraffin gray

- Golden paraffin

- For the treatment of osteochondrosis and other joint diseases, you can make a kind of cake from melted paraffin (after some hardening of the melted composition). The made plate is placed on the affected joint, wrapped with a film and a woolen scarf. The compress is also kept on the affected area for no more than 20 minutes.

- Paraffin can be applied to inflamed areas using a suitable brush. The substance is melted until a liquid consistency is achieved and applied to the affected area with a brush in several layers. Wait for the hardening of the product should not be. The treated area is wrapped with a film and a scarf. Such a compress can be maintained on the skin for an hour.

For example, adding fir or ginger oil to melted paraffin will allow you to get rid of pain during an exacerbation of a joint disease, and also partially relieve inflammation after the first application.

Paraffin compresses are used every day. But you should be careful in applying heat therapy, since excessive heating of the joint can turn into troubles for the user.

That's all. He hugged everyone. Sergey Mauser. Come for paraffin here

Bottle wax

April 6, 2020Which company or store will seem more successful to you: Where in a modest box are modest bottles of wine with ordinary corks or where is a chic stand with chic bottles of wine, sealed with wax?

What is the best way to see clients, each of whom rushes inadvertently to a colorful stand to take a chic bottle of wine, sealed with wax, or or send them to a modest wine box with ordinary corks?

We have been doing bottle waxing since 2020 and we know everything about it.

Wax for capping bottles from the manufacturer wholesale and retail with delivery throughout Russia.

We offer wax for capping bottles wholesale and retail with delivery throughout Russia. A large palette of colors. Specially developed formula that gives tightness, strength, high adhesion to glass, resistance to cold and heat.Benefits of Wax

Stylish design for your products with Russian-made bottle wax.High adhesion to glass, durable, does not crumble, withstands cold and heat.

A large palette of colors and dozens of ready-made ideas for using wax for decorative purposes.

It can be implemented both in mass and single production using automatic or semi-automatic lines, as well as the manual method.

Increases product recognition. Stands out on a shelf. Protects products from fakes.

The use of polylaminate and heat shrink capsules is not required.

Bottle Wax: Features and Benefits

Bottle wax is characterized by increased adhesion, that is, the ability to adhere to smooth surfaces and not allow water and air to pass through. This feature determines the content in the mixture of resin.The material is insensitive to moisture and has high strength. In addition, the particles of minerals contained in the wax are larger than, for example, in a mixture for sealing letters. This makes it thick, so the wax on the bottle does not flow well and solidifies quickly.

WAX APPLICATION INSTRUCTIONS FOR BOTTLE CAP

You will need:

- Water bath (device for heating substances when the required temperature is up to 100 ° C).

- Thermometer with probe.

Procedure:

- Place the wax in a water bath.

- Stir periodically, heat the wax to a temperature of 90 ° C - until the wax is completely dissolved and a homogeneous mass is formed.

- Prepare the items to be waxed. The surface on which the wax is applied must be at room temperature.

- Allow the wax to cool. The base optimum wax temperature is 68 ° C. To give different effects, the temperature can be varied (from 60 ° C to 78 ° C). At 60 ° C, the wax will be thicker and the applied layer will be thicker. At 78 ° C, the wax will be more liquid and the applied layer will be thinner. When applying, it is recommended to maintain a constant temperature of the wax.

- Dip the bottle into the wax to the desired level.

- Carefully remove the bottle by spinning it to evenly distribute wax and drain excess. To achieve various effects, you can dive at different angles, vary the depth and speed of dipping. Additional blowing will speed up the hardening of the wax.

- Put the product to dry. The product will be ready to move 1 minute after waxing. The final hardening of the wax occurs within 1-2 hours.

Bottle wax for capping different colors 400gr.

Reasons to use bottle wax:

- Creates tightness

- Durable - does not crumble, does not crack

- Withstands frost and heat

- Good adhesion to glass

- The product looks more expensive

- Stand out on a shelf

- Stylish design

Bottle wax application technology:

A modern and stylish way to clog bottles. The neck of the bottle is immersed in wax. At high temperatures, the wax softens. After drying, it takes on a permanent form. It attaches well to glass, cloth and other surfaces.Wine bottle waxes have been used for centuries to seal bottles. It is very simple to use, it is necessary to melt the wax, then dip the neck of the bottle into it to the desired level.

The unique formula of bottle wax , thanks to which the wax does not crack, does not crumble, does not crumble from the surface.

Clogging process

At the initial stage, grind the wax into small pieces. Then you need to put the raw materials in a can of canned food and heat the water in a pan, filled by one third. Next, you need to lower the tin can with wax into a hot liquid (observing safety precautions), and put the pan on a slow fire. Soon after, the wax will begin to melt. To achieve a uniform consistency, stir the composition periodically.

At the same time, bottle caps must be aligned (masking tape can be used). At the next stage, the bottles are cooled, and then the plugging process takes place directly (it is important to ensure that they surround the bottle necks as tightly and evenly as possible). It remains to plug our containers with liquid wax. To do this, lower the neck of the bottle into the pan with the resulting composition for 2 minutes, after which they should be removed, wait 20-25 minutes until the wax has hardened, and the glass containers can be transferred to the place of their direct storage.

Stylish design for your products with Russian-made bottle wax.

HOW DOES BOTTLE WAX BE USED?

Nowadays, not only VOSKOM bottle capping is used, but also surface decoration with a WAX impression. To do this, containers of a certain shape are blown out with a recess under the Wax mixture, where the impression is placed. To give more importance to the design, red color is usually used. For example, the producers of the French Grand Marnier liquor, who keep the tradition of production since the 19th century, do this. This is one of the few liquors that has a fortress of 40 degrees, as well as a pronounced cognac aftertaste and the aroma of an orange. The red seal is intended to emphasize its distinctive features.Producers planning long-term storage of wine can also seal the bottle with WAX. For example, for scientific purposes or for the commercialization of the process for the sale of long-term aged drinks at prices many times higher than the cost of wines two to three years ago.

WAX sealed the Massandra wine collection, listed in the Guinness Book of Records. It has been formed since the end of the 19th century and includes many unique wines, including the sherry of 1775. On average, replacing the cork and refilling the Wax mixture is done every 20 years.

Today, VOSK is actively used by the creators of copyrighted wine collections in private wineries. This is partly due to the lack of production facilities and automated lines for durable bottle corking and tightness. In addition, this design increases the credibility of the author’s collection in the eyes of potential consumers.

THAT'S ALL I WANTED TO SAY. ALL HUGS. COME BEYOND THE WAX HERE

Подробнее: https://xsvechi.com/p57995403-forma-dlya-hozyajstvennyh.html

Комментарии

Отправить комментарий